Susie Jones

Lkw-Fahrer fordern eine Reform der Branche

Erstellt: 05.02.2025

•

Aktualisiert: 05.02.2025

Derzeit beträgt der Anteil der weiblichen Lkw-Fahrer im Vereinigten Königreich nur 1 % aller Fahrer - eine Zahl, die in den letzten zehn Jahren um 144 % gestiegen ist, da mehr Initiativen zur Förderung der Vielfalt und zur Schließung der Lücke im Fahrermangel eingeführt wurden.

In einem Fleetpoint-Artikel werden die vielen Möglichkeiten beschrieben, wie die Branche mehr Frauen für die Branche gewinnen könnte:

Schaffung eines unterstützenden und einladenden Arbeitsumfelds.

Verbesserung der Infrastruktur und der Einrichtungen.

Flexible und familienfreundliche Arbeitsregelungen.

Schaffung klarer Wege für die berufliche Entwicklung.

Trotzdem argumentierten die Fahrer in [sozialen Medien] (https://www.facebook.com/photo/?fbid=988050383364634&set=a.482170237285987&locale=en_GB), dass diese seit langem bestehenden Herausforderungen in der Branche für alle angegangen werden müssen, bevor neue Initiativen zur Behebung des Fahrermangels ergriffen werden.

Fahrermangel - wo steht die Branche jetzt?

Der Fahrermangel war schon immer ein Problem für die Transportbranche, aber nach COVID-19 und Brexit hat er ein kritisches Ausmaß erreicht. Im Jahr 2024 fehlten in Europa, Norwegen und dem Vereinigten Königreich mehr als [233.000] (https://www.iru.org/news-resources/newsroom/half-european-truck-operators-cant-expand-due-driver-shortages#:~:text=More%20than%20half%20of%20European,no%20significant%20action%20is%20taken.) Lkw-Fahrer - eine Zahl, die bis 2028 aufgrund einer alternden Erwerbsbevölkerung 745.000 übersteigen wird.

Die Branche hat noch immer mit den Folgen zu kämpfen und arbeitet an der Umsetzung neuer Initiativen zur Förderung der Vielfalt, zur Verbesserung der Arbeitsbedingungen und zur Schließung der Arbeitskräftelücke.

Die Regierung hat etwa [33](https://www.gov.uk/government/topical-events/hgv-driver-shortage-uk-government-response/about#:~:text=We%20extended%20dangerous%20goods%20(ADR,to%20take%20refresher%20training%20now.) Maßnahmen ergriffen, um dem Mangel an LKW-Fahrern im Vereinigten Königreich zu begegnen. Dazu gehören unter anderem:

Steigerung der Effizienz in bestehenden Lieferketten.

Unterstützung und Schulung für neue Lkw-Fahrer.

Erweiterung der Kapazitäten für die Prüfung von Lkw-Fahrern.

Verbesserung der Genehmigungsverfahren.

Verbesserung der Bedingungen.

Sicherstellung der Stabilität der Kraftstoffversorgungskette.

Was muss sich ändern? Die Autofahrer haben das Sagen.

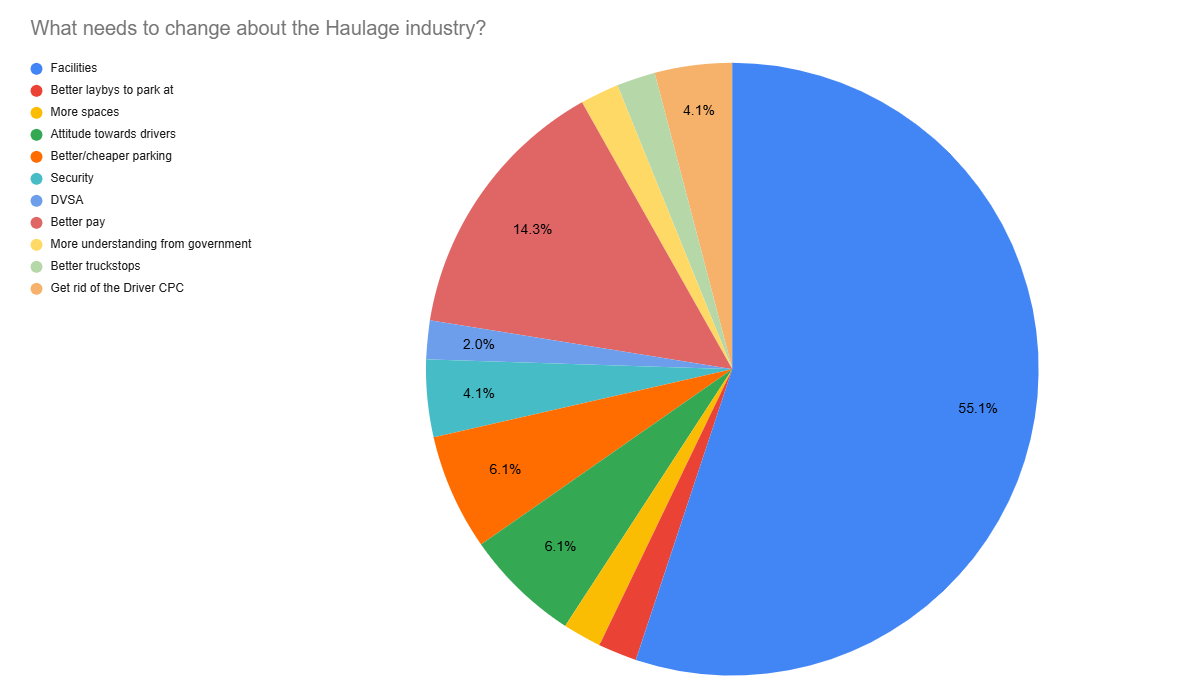

49 % der Fahrer in den sozialen Medien sprachen sich dafür aus, dass Veränderungen unabhängig vom Geschlecht umgesetzt werden müssen - wobei 27 % der weiblichen Lkw-Fahrer der Meinung waren, dass sich der Sektor für alle weiterentwickeln muss. 24 % gaben an, der Beruf sei nicht mehr attraktiv, was die Notwendigkeit von Veränderungen in der Branche unterstreicht. Was wollen die Fahrer also geändert sehen?

Einrichtungen

55 % wünschen sich eine Verbesserung der Einrichtungen für alle:

"Es muss bessere Einrichtungen und eine bessere Behandlung geben, ganz einfach. Die ganze Branche ist ein Scherbenhaufen, und wir werden schlecht behandelt.

"Die Annehmlichkeiten sind für alle Fahrer, Männer und Frauen, schrecklich.

Im November 2024 ergab eine [Transport Focus-Umfrage] (https://www.britsafe.org/safety-management/2024/uk-truckers-why-more-action-is-needed-to-make-their-working-lives-safer-and-healthier#:~:text=Improving%20roadside%20facilities&text=Drivers%20have%20long%20been%20telling,asked%20expressed%20dissatisfaction%20with%20both.), dass zwei Drittel der Fahrer mit den Einrichtungen von Truckstops unzufrieden sind - schmutzige Einrichtungen, schlechte Verpflegungsmöglichkeiten und ein Mangel an Sozialräumen sind dabei die Hauptprobleme.

Die Regierung und das Transportgewerbe haben wichtige Maßnahmen ergriffen und 14 Millionen Pfund investiert, um Innovationen voranzutreiben und die Arbeitsbedingungen zu verbessern.

Im Oktober 2024 erhielten 23 erfolgreiche Bewerber bis zu 4,5 Millionen Pfund für die Modernisierung ihrer Raststätten. Die Modernisierungen umfassen neue Duschen, Restaurants und verbesserte Sicherheitsvorkehrungen, um den Fahrern mehr Sicherheit zu bieten. Darüber hinaus werden im Rahmen der Maßnahme rund 430 Parkplätze für Lastkraftwagen geschaffen.

Lohn

An zweiter Stelle steht eine bessere Bezahlung: 14 % der Fahrer gaben an, dass höhere Löhne einen Anreiz für den Einstieg in die Branche darstellen würden:

"Es für alle attraktiv machen, die Löhne erhöhen".

Die Erhöhung der Löhne wird für die Branchenführer mit erheblichen Kosten verbunden sein. Würde das Durchschnittsgehalt eines Lkw-Fahrers entsprechend dem "National Living Wage" angehoben, könnten die Fuhrparkbetreiber mit zusätzlichen 1,5 Milliarden Pfund pro Jahr rechnen.

Dennoch werden Investitionen die Verbleibsquoten verbessern, die Einstellungskosten senken und die Ausbildungskosten verringern. Höhere Gehälter würden den Beruf nicht nur für Neueinsteiger attraktiver machen, sondern auch die entscheidende Rolle der Fahrer bei der Aufrechterhaltung der Lieferkette anerkennen.

Einstellung gegenüber Fahrern

Im Laufe der Jahre hat sich die öffentliche Meinung über Lkw-Fahrer stark gewandelt. Das Leben eines Lkw-Fahrers wurde in Filmen und populären Medien oft romantisch dargestellt - was viele glauben ließ, sie hätten es leicht. Allerdings wurden sie auch als hart arbeitende Helden dargestellt - ein Image, das sich im Laufe der Zeit verschlechtert hat.

Gegen Ende des 20. Jahrhunderts änderte sich die Wahrnehmung, als die Arbeitsbedingungen härter wurden und die Lkw-Fahrer mit ungerechten Stereotypen belegt wurden - oft aufgrund falscher Darstellungen in den Medien und manchmal aufgrund einiger weniger unerfahrener Fahrer. Diese negativen Stereotypen wurden während der COVID-19-Pandemie abgeschwächt, als die öffentliche Wertschätzung für Lkw-Fahrer zunahm.

Heute werden Lkw-Fahrer respektiert, doch die Branche ist nach wie vor von negativen Stereotypen und Einstellungen geprägt. Etwas, das 6 % der Fahrer gerne ändern würden:

"Wenn ich an Covid zurückdenke, galten wir als Helden, aber danach wurde es wieder normal. Es ist kein Wunder, dass die derzeitigen Fahrer, Männer wie Frauen, die Branche verlassen wollen. Sie haben die Nase voll von der miserablen Behandlung, die sie täglich erfahren.

"Es wäre schön, wenn man nicht wie Abschaum behandelt würde."

In den letzten Jahren hat der Aufstieg der sozialen Medien dazu geführt, dass negative Wahrnehmungen in Frage gestellt und verändert werden. Viele Fahrer nutzen Plattformen wie TikTok und Instagram, um Einblicke in ihre Rolle zu geben, Missverständnisse auszuräumen und sich den Respekt von Außenstehenden zu verdienen.

Die Rückmeldungen zeigen, dass das Transportgewerbe dringend Änderungen vornehmen muss, um bestehende und neue Fahrer anzuziehen und zu halten. Die Unterrepräsentation von Frauen ist nach wie vor eine große Herausforderung, und Investitionen in Einrichtungen, die ihren Bedürfnissen gerecht werden, sind von entscheidender Bedeutung. Diese Investitionen müssen jedoch integrativ sein und der gesamten Belegschaft zugute kommen.

In welchen Ländern fehlen Lkw-Fahrer?

Die europäischen Länder sind am stärksten betroffen. Viele Speditionsunternehmen können ihr Geschäft nicht ausbauen, weil sie keine qualifizierten Arbeitskräfte finden können.

Europa hat eine alternde Lkw-Fahrerpopulation mit einem [Durchschnittsalter von 47 Jahren] (https://www.iru.org/news-resources/newsroom/half-european-truck-operators-cant-expand-due-driver-shortages#:~:text=The%20EU%2C%20Norway%20and%20the,an%20average%20age%20of%2047.). Ein Drittel der Lkw-Fahrer ist über 55 Jahre alt und wird voraussichtlich in den nächsten zehn Jahren in Rente gehen. Darüber hinaus sind weniger als 5 % der Lkw-Fahrer in Europa jünger als 25 Jahre - was die Lücke verdeutlicht, die entstehen wird, wenn eine alternde Belegschaft in den Ruhestand geht.

Gibt es einen Tag der Wertschätzung für Lkw-Fahrer?

Der [HGV Drivers Day] (https://https://snapacc.com/newsroom/hgv-drivers-day-2025-giving-truckers-a-voice/) findet am 22. Januar statt und wurde von NN1 Personnel ins Leben gerufen. Der Tag zielt darauf ab, Lkw-Fahrer und alles, was sie für die Wirtschaft und die Gesellschaft tun, zu feiern.

Wie sind die Aussichten für die Lkw-Branche im Jahr 2025?

In unserem Blog [The Road Ahead for 2025] (https://snapacc.com/newsroom/the-road-ahead-for-2025-truck-industry-trends-to-expect/) gehen wir davon aus, dass in der Lkw-Branche in diesem Jahr folgende Themen im Vordergrund stehen werden:

Die Vorteile der KI nutzen.

Bekämpfung des Geschlechtergefälles und des Fahrermangels.

Förderung einer umweltfreundlicheren Industrie.

Zunahme des Güterfernverkehrs.