Guest

Gorivo proti polnjenju: Je prehod na elektriko cenejši ali le bolj zelen?

Ustvarjeno: 28. 07. 2025

•

Posodobljeno: 19. 09. 2025

Razmah električnih polnilnih postaj za težka tovorna vozila po vsej Evropi je povzročil prehodno obdobje na obsežnih cestnih omrežjih celine. Številni upravljavci voznih parkov in vozniki še vedno uporabljajo klasična tovorna vozila na dizelski pogon. Vendar se zaradi nadaljnjega razvoja panoge obeta prehod na električna težka tovorna vozila.

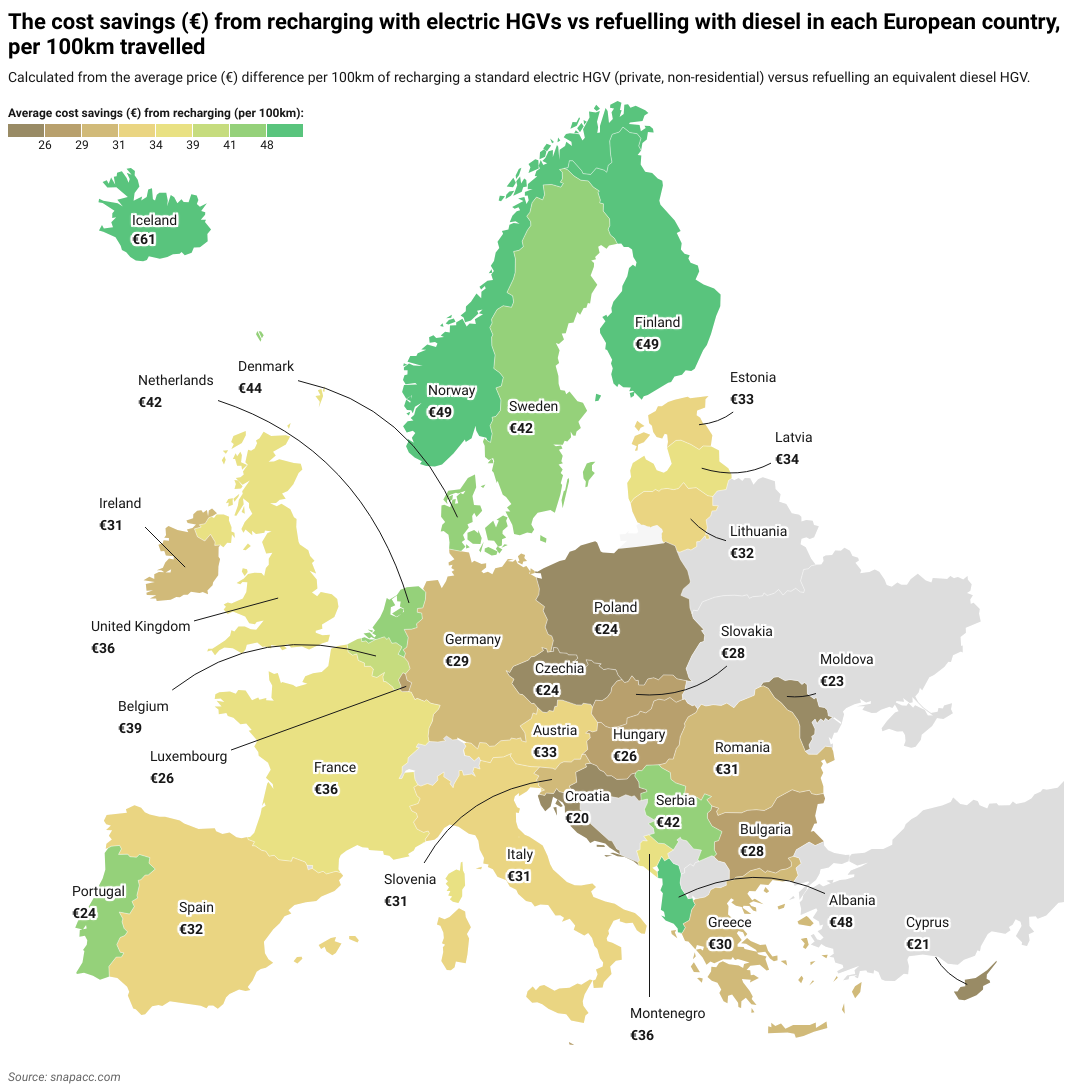

Za oceno izvedljivosti prehoda upravljavcev voznega parka z dizelskega na električni pogon je SNAP pripravil raziskavo o stroških polnjenja težkih tovornih vozil v primerjavi s polnjenjem na različnih evropskih tovornih poteh. Izračunali smo prihranke električne energije v primerjavi z dizelskim gorivom v evrih na 100 km v 35 evropskih državah.

Ugotovili smo, da je Islandija vodilna s povprečnim prihrankom stroškov v višini 61,03 EUR na 100 km, nordijske države Norveška in Finska pa so na drugem oziroma tretjem mestu po višini prihrankov. Na drugi strani lestvice je najmanj stroškov prihranila Hrvaška, in sicer 19,96 EUR na 100 km, sledita pa ji Ciper in Moldavija.

V tem članku razkrivamo prihranke stroškov po evropskih državah in analiziramo nekatere prihranke stroškov po evropskih državah ter analiziramo nekatere zunanje dejavnike, ki bi lahko vplivali na te prihranke. Poglobimo se tudi v to, kakšna je lahko prihodnost vozil eHGV v Evropi ter kako lahko vozila eHGV pomagajo upravljavcem voznih parkov in voznikom prihraniti denar, zlasti pri vozniških proračunih.

Kako se stroški vozil eHGV in dizelskega goriva gibljejo po EU

Naša raziskava je pokazala, da je v vseh preučevanih evropskih državah uporaba eHGV z električnim polnjenjem prihranila denar v primerjavi z uporabo tradicionalnega težkega tovornega vozila z gorivom. Glavna razlika je bila v tem, koliko so se prihranki stroškov razlikovali. Na primer, cena električne energije v najdražji državi, Islandiji, je 206 % višja (41 EUR) kot v najcenejši državi, Hrvaški.

Ugotovili smo, da bo voznik električnega tovornega vozila v primerjavi z voznikom dizelskega tovornega vozila v povprečju prihranil 30,59 EUR na 100 km. To pomeni, da vozniki električnih težkih tovornih vozil na dolge razdalje v povprečju prihranijo 37 200 EUR* na leto, vozniki na domačem trgu pa 24 800 EUR*.

Pri zbiranju podatkov smo pregledali 35 evropskih držav in primerjali stroške energije ali goriva na 100 km za dve vrsti težkih tovornih vozil (HGV). Šlo je za standardno dizelsko težko tovorno vozilo, pri katerem je poraba goriva znašala 35 litrov na 100 km po povprečni maloprodajni ceni dizelskega goriva v vsaki državi, in električno težko tovorno vozilo, pri katerem je poraba električne energije znašala 108 kWh na 100 km na podlagi povprečne cene električne energije za negospodinjstva. DDV in vračljivi davki so bili iz teh izračunov izključeni. Primerjava odraža samo neposredne stroške "na črpalki" ali "na vtičnici" brez upoštevanja dejavnikov, kot so velikost voznega parka, sklenjene pogodbe o dobavi energije ali prihodnje spremembe cen goriva in električne energije.

Pri raziskovanju cen dizelskega goriva in električne energije so bili uporabljeni številni viri, med drugim Eurostat, CEIC, GlobalPetrolPrices, Webfleet in Gov.uk. Opozoriti velja, da se nekateri od teh virov nanašajo na "Veliko Britanijo", drugi pa na "Združeno kraljestvo". Za namene te raziskave sta bila oba izraza obravnavana kot zamenljiva.

Države, ki s prehodom na električna tovorna vozila prihranijo največ

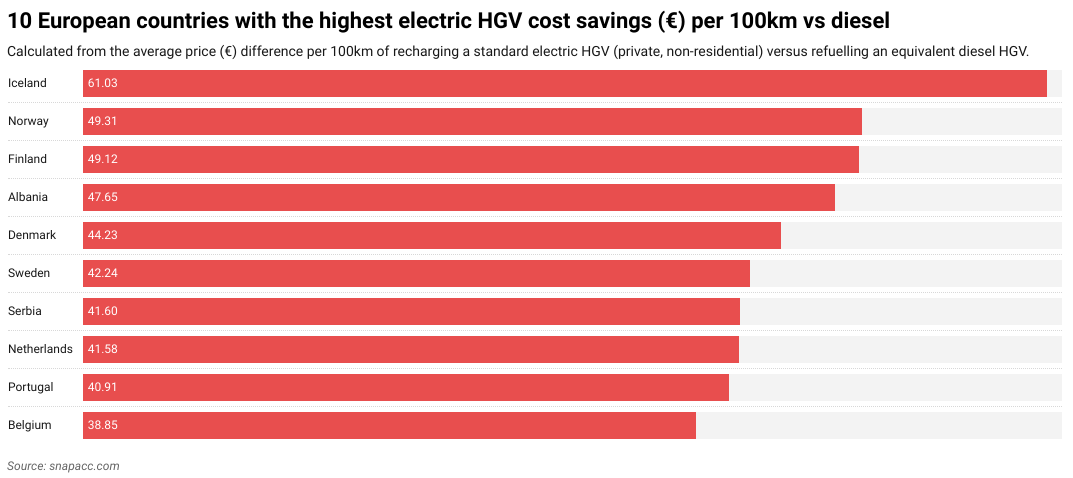

Islandija (61,03 EUR), Norveška (49,31 EUR) in Finska (49,12 EUR) so trenutno države, v katerih je mogoče največ prihraniti s prehodom na električna tovorna vozila.

To je predvsem posledica tega, da so te države med najdražjimi v Evropi za dizelsko gorivo. Islandija je najdražja država v Evropi za dizelsko gorivo (2,07 EUR na liter). Ta visoka cena je v veliki meri posledica geografske izoliranosti v primerjavi s preostalo Evropo, zaradi česar so stroški uvoza dizelskega goriva veliko višji kot v drugih evropskih državah. Islandija je tako kot Norveška in Finska znana tudi po visoki davčni stopnji, ki prav tako prispeva k visokim stroškom goriva.

Norveška (32 %) in Islandija (18 %) sta prav tako dve državi na vrhu na svetu po deležu električnih avtomobilov na cestah med vsemi osebnimi avtomobili na cestah. Zato sta obe državi veliko vlagali v infrastrukturo za polnjenje električnih avtomobilov.

Islandija je majhna in ima glavno obvoznico, zato je tudi lažje v rednih časovnih presledkih namestiti električne polnilne postaje za voznike električnih tovornih vozil. Enako utemeljitev lahko delno uporabimo tudi za druge države z manjšimi omrežji, ki imajo visoko stopnjo prihrankov stroškov, vključno z Albanijo, Srbijo in Belgijo - čeprav je treba opozoriti, da imajo vse tri tudi nekatere od najdražjih cen dizelskega goriva v Evropi, kar prispeva k razliki v prihrankih stroškov.

Spodnja tabela prikazuje 10 držav z največjimi prihranki pri uporabi električnih tovornih vozil:

"Vozniki po vsej Evropi že varčujejo s prehodom na električna tovorna vozila. Prehod na polnjenje električnih tovornih vozil je prihodnost panoge in SNAP je pripravljen pomagati voznikom in upravljavcem voznih parkov pri tem prehodu. "

Matthew Bellamy - upravni direktor v podjetju SNAP

Države, ki s prehodom na električna tovorna vozila prihranijo najmanj

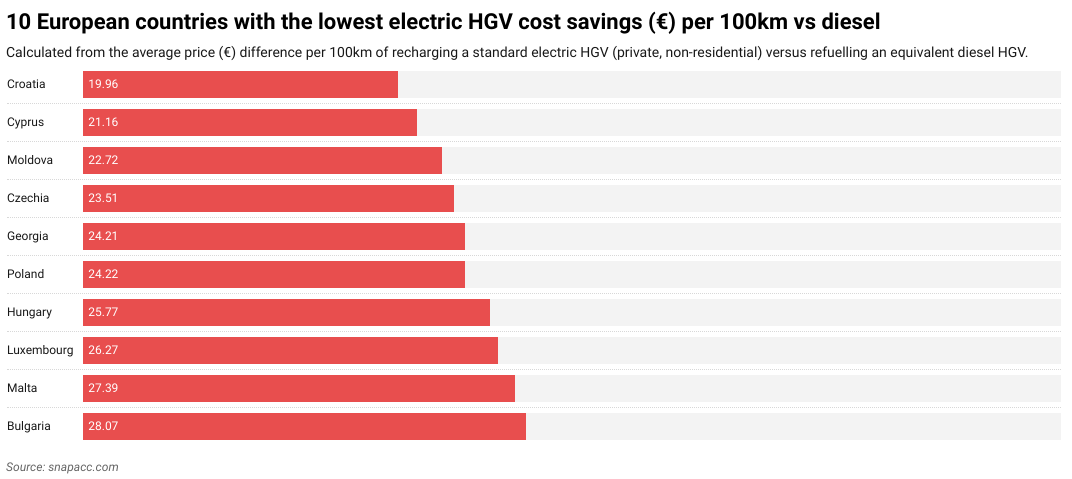

Hrvaška (19,96 EUR), Ciper (21,16 EUR) in Moldavija (22,72 EUR) so trenutno tri države z najnižjimi prihranki v Evropi.

Hrvaška ima drugo najpočasnejšo stopnjo uporabe električnih vozil v EU, takoj za Poljsko. Deloma je to posledica slabe hrvaške infrastrukture za polnjenje električnih vozil, kot so polnilne postaje, pri katerih je treba poklicati službo za pomoč uporabnikom ali uporabiti več različnih aplikacij za začetek postopka polnjenja, slabe usmeritve za polnilne postaje zunaj glavnih avtocest in potencialno dolge čakalne dobe na vrhuncu turistične sezone. Poleg tega na Hrvaškem ni polnilnih postaj za zelo visoke hitrosti (180 kW in več), kar je lahko težava za električna težka tovorna vozila, ki potrebujejo več energije kot povprečno električno vozilo.

Ciper in Moldavija imata notranja geopolitična vprašanja, ki otežujejo načrtovanje infrastrukture za polnjenje električnih vozil (kot tudi nacionalno načrtovanje na splošno). Na Cipru je severna polovica otoka - vključno s polovico glavnega mesta Nikozija - od leta 1974 okupirana s strani Turške republike Severni Ciper, ki jo podpira Turčija. Za Moldavijo vzhodna pokrajina Pridnestrje deluje kot dejanska država z lastno vlado. To pomeni, da obe državi ne moreta dosledno izvajati infrastrukture EV na ozemlju, ki ga štejeta za svoje.

Težave na Cipru so še večje zaradi visokih stroškov električne energije, medtem ko so cene dizelskega goriva v Moldaviji pete najcenejše v Evropi. Moldavija je tudi druga najrevnejša država v Evropi, zaradi česar so naložbe v infrastrukturo za električna vozila velik izziv. Vsi ti dejavniki prispevajo k nizkim splošnim prihrankom pri stroških električnih tovornih vozil.

Tudi Poljska je nizko na seznamu s prihrankom stroškov v višini 24,22 EUR. Kljub impresivni gospodarski rasti in vse večjim naložbam v infrastrukturo za polnjenje električnih vozil je pokritost na nekaterih območjih države še vedno problematična, čeprav se bo to v prihodnosti verjetno spremenilo (https://alternative-fuels-observatory.ec.europa.eu/general-information/news/poland-launches-major-funding-programs-zero-emission-transport).

Države, kot so Španija (32,20 EUR), Romunija (30,62 EUR) in Irska (30,54 EUR), so na sredini poti, ko gre za prihranek stroškov za električna tovorna vozila. To je verjetno posledica tega, da imajo te države vedno bolj razvito infrastrukturo za polnjenje električnih vozil ter srednje visoke cene električne energije in dizelskega goriva.

Spodnja tabela prikazuje 10 držav, v katerih so prihranki pri uporabi električnih tovornih vozil najnižji:

Prihranki stroškov električnih tovornih vozil v Združenem kraljestvu

V Združenem kraljestvu so prihranki pri stroških električnih tovornih vozil znašali 36,23 EUR, kar ga uvršča na 11. mesto na svetu po prihrankih pri stroških polnjenja na 100 km. To je predvsem posledica visokih cen goriva v Združenem kraljestvu, saj so cene dizla tretje najdražje v Evropi. Čeprav prihranki zaradi visokih cen dizelskega goriva vsekakor prispevajo k visokim prihrankom pri stroških eHGV v Združenem kraljestvu, bi bili ti verjetno veliko višji, če električna energija v Združenem kraljestvu ne bi bila tudi med najdražjimi v Evropi.

Tudi v Združenem kraljestvu pričakujejo izboljšanje infrastrukture za polnjenje električnih vozil. Britansko podjetje Moto, ki se ukvarja s storitvami na avtocestah, aktivno načrtuje izgradnjo 15 "superhub" do leta 2027. Ti superhubi lahko učinkoviteje kot standardne polnilnice za električna vozila prilagodijo polnjenje električnih vozil eHGV. Na britanskih cestah je trenutno manj kot pet posebnih polnilnih mest za vozila eHGV. Ker nameravajo vlagati tudi druga podjetja, kot sta BP Pulse in Aegis Energy, se zdi verjetno, da bo Združeno kraljestvo v bližnji prihodnosti imelo precej izboljšano omrežje za polnjenje težkih tovornih vozil.

Kaj vpliva na elektrifikacijo težkih tovornih vozil?

Na elektrifikacijo težkih tovornih vozil trenutno vpliva več dejavnikov, vključno s pomanjkanjem polnilne infrastrukture, dolgim časom polnjenja, visokimi začetnimi stroški predelave eHGV in njihovim omejenim dosegom. Poleg tega so zaradi razmeroma nizkih stroškov in dostopnosti dizelskega goriva in vozil tradicionalna težka tovorna vozila privlačna možnost za [upravljavce voznih parkov] (https://snapacc.com/fleet-operators/).

Vendar se vsi ti vplivi lahko razlikujejo glede na državo delovanja. Na primer, če vaš vozni park obratuje le na domačem trgu v državi, kot sta Norveška ali Islandija, bo verjetno manj prizadet kot vozni park, ki obratuje po vsej Evropi ali v regijah s slabšo infrastrukturo eHGV, na primer na Balkanu.

Nezadostna infrastruktura za polnjenje

Glavna ovira za elektrifikacijo težkih tovornih vozil je nezadostna infrastruktura za polnjenje eHGV. To je zato, ker vozila eHGV zahtevajo megavatno polnjenje, ki ga večina obstoječih polnilnih mest za osebna vozila (standardni električni avtomobili in kombiji) ne podpira.

V Evropi je veliko držav, v katerih takšne infrastrukture zelo primanjkuje, zlasti na glavnih tovornih poteh in postajališčih za tovornjake. To so običajno revnejše države v južni in vzhodni Evropi, kot so Moldavija, Gruzija in Bolgarija. Ni naključje, da se te države uvrščajo v spodnjo deseterico držav, kjer se prihranijo stroški z eHGV.

Lahko se tudi zgodi, da polnilne postaje za vozila eHGV obstajajo, vendar so na območjih, ki zaradi šibkega lokalnega električnega omrežja preprosto ne morejo sprejeti več vozil eHGV, ki se polnijo čez noč. To je pogosto težava v bolj podeželskih in oddaljenih delih Evrope.

Čeprav mnoge evropske države načrtujejo izboljšanje infrastrukture za eHGV, je to še vedno dolgotrajen in drag proces s številnimi birokratskimi, logističnimi in tehničnimi ovirami, ki jih je treba premagati - da ne omenjamo okoliških infrastrukturnih posodobitev, kot so povezave z lokalnim omrežjem, ki bodo prav tako potrebne.

Dolgi časi polnjenja

Električna tovorna vozila se polnijo veliko dlje kot standardna električna vozila. To pomeni, da se morajo pogosto polniti čez noč. Tudi če je mogoče pridobiti hitre polnilnice za vozila eHGV, postopek še vedno traja vsaj dve uri in ne le nekaj minut, kot je to značilno za bencinska vozila.

Ta dolgi čas polnjenja ima lahko za upravljavce voznih parkov posledice v smislu časa obratovanja. V panogi, kjer so urniki in roki za dostavo zelo kratki, je to lahko škodljivo za poslovno uspešnost.

Omejena ponudba vozil eHGV

Električna težka tovorna vozila so omejena tudi zaradi relativno omejenega dosega v primerjavi s kilometrskim dosegom, ki ga omogočajo tradicionalna težka tovorna vozila. Po podatkih podjetja Safety Shield ima tipično električno težko tovorno vozilo z enim polnjenjem doseg približno 300 milj (približno razdalja od Londona do Rotterdama). Tipično težko tovorno vozilo na dizelski pogon pa lahko z enim rezervoarjem goriva prevozi do 1000 milj (približno razdalja od Londona do Varšave).

Na prevožene kilometre električnih tovornih vozil lahko bolj vplivajo tudi zunanji dejavniki, kot so obremenitev, hladno vreme in teren. To lahko pri voznikih povzroči tesnobo glede dosega, zato se lahko pogosteje polnijo, da bi si zagotovili dovolj energije za prihod na cilj. To pa lahko privede do zamud pri dostavi, zlasti pri vožnji skozi države s slabo infrastrukturo za polnjenje vozil eHGV.

Zaradi vsega tega je optimizacija poti ključnega pomena za upravljavce voznih parkov, ki načrtujejo vožnje za svoja vozila eHGV. Opozoriti je treba, da se tehnologija baterij nenehno razvija in da se bo v bližnji prihodnosti zmogljivost - in s tem število prevoženih kilometrov - še naprej izboljševala.

Visoki stroški eHGV

Začetni stroški eHGV so visoki (običajno med 160.000 in 200.000 funtov v primerjavi z 80.000 in 100.000 funtov za dizelsko težko tovorno vozilo), kar lahko odvrne neodvisne voznike in manjše upravljavce voznih parkov od tega, da bi si ga izposodili. Razlog za to je predvsem strošek tehnologije akumulatorjev. To pomeni, da bo nakup novega električnega težkega tovornega vozila drag, saj je tehnologija v njem dražja kot pri dizelskem težkem tovornem vozilu.

Visoki začetni stroški nakupa vozil eHGV pomenijo tudi, da se bodo upravljavci voznih parkov v državah s cenejšo električno energijo za polnjenje vozil eHGV, kot so Norveška, Švedska ali Finska, pogosteje odločali za prehod, saj se jim bo naložba povrnila hitreje kot upravljavcem v državah z drago električno energijo, kot sta Irska in Hrvaška.

Cene električne energije lahko nihajo tudi zaradi različnih dogodkov. V zadnjih petih letih so na primer cene električne energije nihale zaradi odpiranja gospodarstev po pandemiji COVID-19 in nato zaradi ruskega vdora v Ukrajino leta 2022 (zlasti slednji je imel velike posledice za evropsko oskrbo z energijo). Posledično je v obdobju po invaziji prišlo do skoraj 30-odstotnega skoka cen električne energije, in sicer z 20,5 c€/kWh, na 26,5 c€/kWh za povprečno prestolnico EU. Ker pa je povprečje EU zdaj nižje kot leta 2022, se zdi, da se bo električno polnjenje tovornih vozil še naprej krepilo.

V Evropi so povprečni stroški vožnje električnega tovornega vozila na razdalji 100 km 20,51 EUR, kar je bistveno manj kot stroški vožnje dizelskega tovornega vozila na isti razdalji, ki znašajo 51,10 EUR.

Z izboljšanjem učinkovitosti in razširjenostjo tehnologije baterij, ki je cenejša za proizvodnjo, bodo tudi vozila eHGV postala cenovno dostopnejša.

Cenovno ugodno in dostopno dizelsko gorivo

Dizelsko gorivo ima še vedno prevladujočo vlogo v industriji težkih tovornih vozil. To je zato, ker je infrastruktura za dizelsko gorivo v Evropi že desetletja dobro uveljavljena, zlasti v primerjavi z električnimi polnilnicami za težka tovorna vozila. Zaradi združljivosti dizelskega goriva s karticami za gorivo in njegove relativno nizke cene ostaja priljubljeno tudi pri upravljavcih voznih parkov tovornih vozil.

Tako kot pri električni energiji tudi vrednost dizelskega goriva po vsej celini niha. Zato se v državah, kot so Moldavija, Gruzija in Malta, kjer je dizelsko gorivo še vedno poceni, lahko zdi, da je ugodneje ostati pri dizelskih tovornih vozilih. V državah, kot sta Islandija in Nizozemska, kjer je dizelsko gorivo razmeroma drago, pa obstaja večja spodbuda za prehod na električna tovorna vozila.

Država s poceni gorivom bo morda tudi bolj zadržana pri obsežnih naložbah v infrastrukturo za eHGV, saj se boji, da bo odvrnila tradicionalne vozne parke težkih tovornih vozil, ki bodo zaradi tega morda izbrali alternativne poti.

Prihodnost električnih tovornih vozil v Evropi

Električna tovorna vozila so dolgoročna prihodnost cestnega tovornega prometa. Ne le, da je njihova uporaba sčasoma cenejša, temveč bodo zaradi hitrega vlaganja v novo infrastrukturo in njene izgradnje postala tudi finančno in strateško veliko bolj donosna.

Poleg gospodarskih koristi so električna tovorna vozila pomembna tudi zaradi svojega prispevka k okoljskim ciljem, kot je Net Zero. Tradicionalna težka tovorna vozila so velika onesnaževala, zato se bodo prihranjene emisije, ki jih bodo proizvedla eHGV, poznale v čistejšem zraku po vsej Evropi.

Naslednji trendi bodo v prihodnosti vplivali na električna tovorna vozila:

- Smart truck parks: Truck parks in the future will evolve to better accommodate eHGVs alongside other smart technological advancements. These truck parks may include up-to-date ultra-fast charging stations, diagnostic machines, battery swap stations, and automated cleaning services, among other features.

- Increased EU regulations: Low Emission Zones (LEZs) already exist in a number of cities (e.g. Paris, Berlin, and Milan) with more European cities likely to follow suit with more stringent EU transport regulations. Fleet operators may opt for eHGVs to meet EU regulations or retrofit their HGVs with cleaner technologies, like smart tachographs.

- AI implementation: AI technology has already had a profound sustainability impact across road haulage — with applications in route optimisation, predictive maintenance, and autonomous vehicle development. Electric vehicles will likely incorporate AI to help drive sustainability in the haulage industry over the coming decades.

- Sustainability: The shift to eHGVs is part of a wider global push toward sustainable living. The effects of extreme weather, including heatwaves and floods across Europe, show no sign of slowing due to climate change. Moving to electric HGVs is one way the world is reducing its dependence on fossil fuels.

- Fuel variety: During the transition to cleaner fuel sources, there will be a variety of HGV types on the road throughout the 2030s. Many will be older diesel models, some will be electric, and others will be powered by alternative fuels such as biofuel made from renewable biomass sources.

Pametnejše upravljanje stroškov eHGV

Električna težka tovorna vozila so prihodnost, o tem ni dvoma. Zaradi ekonomskih in okoljskih koristi bo v prihodnjih letih vse več upravljavcev voznih parkov in voznikov prešlo na električna kombinirana vozila. Kako dolgo bo trajalo to prehodno obdobje, je odvisno od tega, kako hitro bo Evropa razvila svojo polnilno infrastrukturo za eHGV.

Trenutno so na celini velike površine, na katerih vozila eHGV niso izvedljiva in na katerih je zaradi krajšega dosega potrebna obsežna optimizacija poti. Poleg tega lahko začetni stroški odvračajo neodvisne voznike in manjše upravljavce voznih parkov.

Tehnologija in infrastruktura se bosta še naprej izboljševali, na voljo pa so že storitve, namenjene čim enostavnejšemu upravljanju voznih parkov eHGV in s tem povezanih stroškov. Od optimizacije poti in upravljanja voznega parka do zemljevidov za parkiranje in pranje tovornjakov - SNAP poenostavlja prevoz tovornjakov.